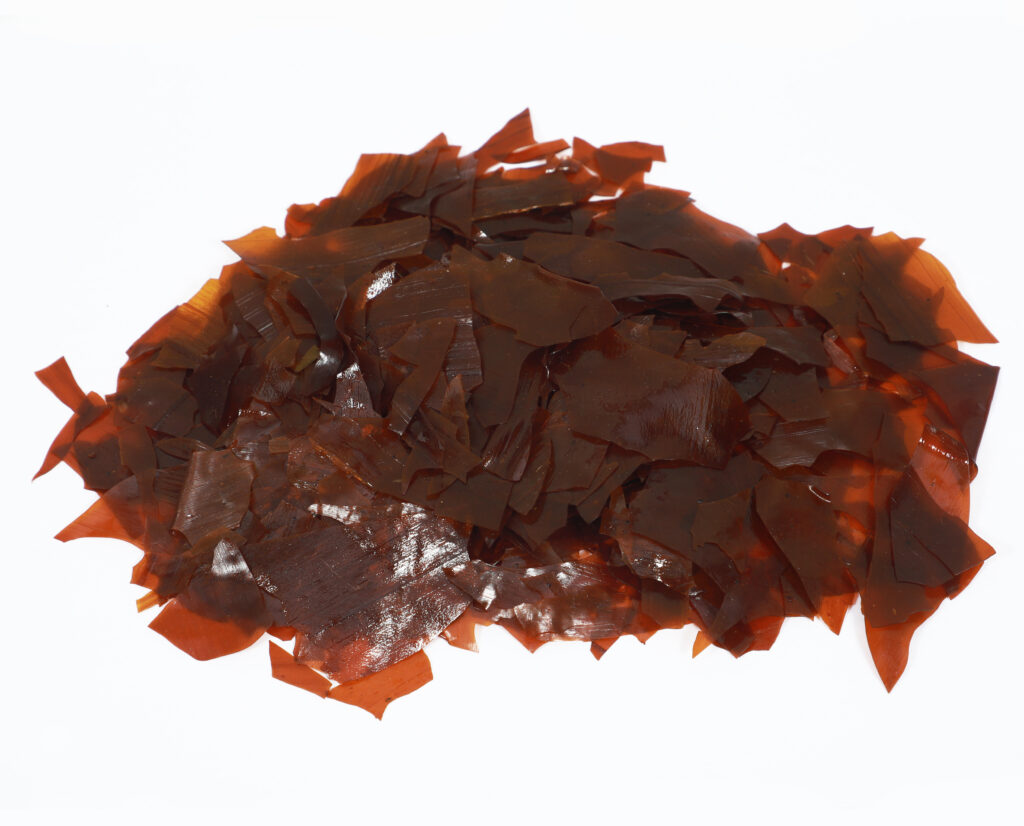

Shellac Flakes - Machine Made

IndoLACCA - LEMON

IndoLACCA - TN

About

The term “Shellac” describes the refined Lac resin in the form of flakes.

The Machine Made Shellac is obtained by the process of hot-filtration, whereas the Seedlac of a suitable grade is used as the raw material.

It is melted using Steam heat inside a specially designed hydraulic press and then filtered out through filter materials to separate the impurities from the Lac resin.

The soft molten refined Lac resin is then further stretched into long continuous sheets of suitable thickness using rollers.

The sheets are then broken into pieces for commercial sale.

Owing to it’s versatile characteristics of corrosive resistance, moisture resistance, electrical insulation and thermoplastics, Shellac has find it’s wide application across various industries from food industry, pharmaceuticals, electrical, cosmetics etc.

We produce the following Machine Made Shellac Flakes under the brand name IndoLACCA ® –

- IndoLACCA ® ORANGE Shellac Flakes

- IndoLACCA ® LEMON Shellac Flakes

- IndoLACCA ® TN Shellac Flakes

- IndoLACCA ® BLACK TN Shellac Flakes

Application

- preparation of Varnish for polishing of Wooden furniture

- in pharmaceuticals for coating of enteric pills

- in textile industry for stiffening of hats

- in engineering applications e.g. rivet fastener, grinding wheels

- in cosmetic industry e.g. in hair lacquer

- as adhesive such as gasket cement, pyrotechnic optical cement

- In electrical, such as in micanite, insulating varnish

- In printing for preparation of flexographic ink, photo engraving, waterproof ink

- In rubber industry as a softening agent

Packaging

- Gunny bags having 50 kgs or 75 kgs Net. Wt. (Export Standard Packaging material)

- Woven bags having 50 kgs or 75 kgs Net. Wt. (Export Standard Packaging material)

- Wooden Box/Cases having 25/50/75 kgs Net. Wt. (Export Standard Packaging material)

Storage

- Store in a cool and dry place

- Store in a well aerated rooms or containers using natural or mechanical aeration and ventilation to avoid risk of formation of lump

SPECIFICATIONS

| PARAMETERS | UNITS | IndoLACCA ® ORANGE Shellac Flakes | IndoLACCA ® LEMON Shellac Flakes | IndoLACCA ® TN Shellac Flakes | IndoLACCA ® BLACK TN Shellac Flakes |

|---|---|---|---|---|---|

| Impurity | % | 0.75 - 1.0 | 0.75 - 1.0 | 0.75 - 1.0 | 1.5-2.0 |

| Colour Index | Max. | 5.0-7.0 | 12.0-15.0 | 7.0-10.0 | 25.0 - 30.0 |

| Acid Value | mg KOH/g | 65.0 - 75.0 | 65.0 - 75.0 | 65.0 - 75.0 | 65.0 - 75.0 |

| Ester Value | mg KOH/g | 115.0 - 170.0 | 115.0 - 170.0 | 115.0 - 170.0 | 115.0 - 170.0 |

| Saponification Value | mg KOH/g | 180.0 - 245.0 | 180.0 - 245.0 | 180.0 - 245.0 | 180.0 - 245.0 |

| Moisture | % | < 2.0 | < 2.0 | < 2.0 | < 2.0 |

| Rosin | % | 0.0 | 0.0 | 0.0 | 0.0 |

| Ash | % | < 0.3 | < 0.3 | < 0.3 | < 0.3 |

| Wax | % | < 5.5 | < 5.5 | < 5.5 | < 5.5 |

| Heavy metal - Lead (as Pb) | ppm | < 10.0 | < 10.0 | < 10.0 | < 10.0 |

| Heavy metal - Arsenic (as AS) | ppm | < 10.0 | < 10.0 | < 10.0 | < 10.0 |

| Flow | mm | >85.0 | >75.0 | >75.0 | > 45.0 |

| Thermal curing time | min | > 25.0 | > 25.0 | > 25.0 | > 25.0 |